MADE IN USA

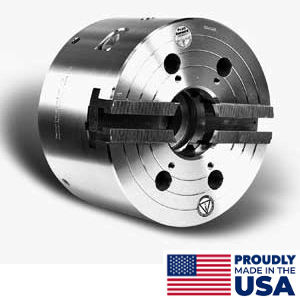

Constant Grip High Speed Thru-Hole Power Chucks

Jaw Presetting Fixture Order number 1009-07090 for use with 6″, 8″, 10″, 12″, 15″, 18″ and 20″ sizes Standard Bore and King Bore Models Quick Change Jaw Power Chucks.

- MADE IN USA

- One Year Warranty

- ±.0005″ Repeatability

- 4-Point Adjusting Feature in the chuck body allows you to true up to virtually zero. Increase Soft Jaw Life by using the adjustment feature instead of skim cutting soft jaws as often. 6 points on 15″ chucks and larger

- High RPM … up to 6,000 using standard top jaws … without loss of gripping force, due to internally counter-balanced design.

- Quick Change Master Jaws, 2 sets supplied with each chuck permits offline pre-assembly of top tooling for next job reducing traditional setup time by 95%.

- SAFE Visual Indicator shows when Master Jaws are in the unlocked mode.

- Master jaws available in 1.5mm x 60° (Japanese type), 1/16″ x 90°, Acme serration and square serration, American Standard tongue and groove.

- Utilize existing top tooling by selecting style of master jaws from 1.5 x 60,1/16″ x 90, Am. Std. Acme, Am. Std Tongue & Groove and Square Serrations or substitute mono block jaws. Sets can be mixed styles.

- Large Thru-Hole Capacity

- Utilize the machine’s existing actuating cylinder – including Japanese types.

- Easy Installation – removable blank sleeve in the chuck allows the customer to bore and thread the sleeve of the chuck to match existing drawtube of drawbar. PBA can supply chuck sleeve pre-threaded on request, at a nominal charge.

- Optional Jaw Setting Fixture for presetting top jaws off the machine for the next job, while the machine is still running. A real timesaver!

- Sizes 6″, 8″, 10″, and 12″, diameters…other sizes available on request.